Cropteq

About CropTeq

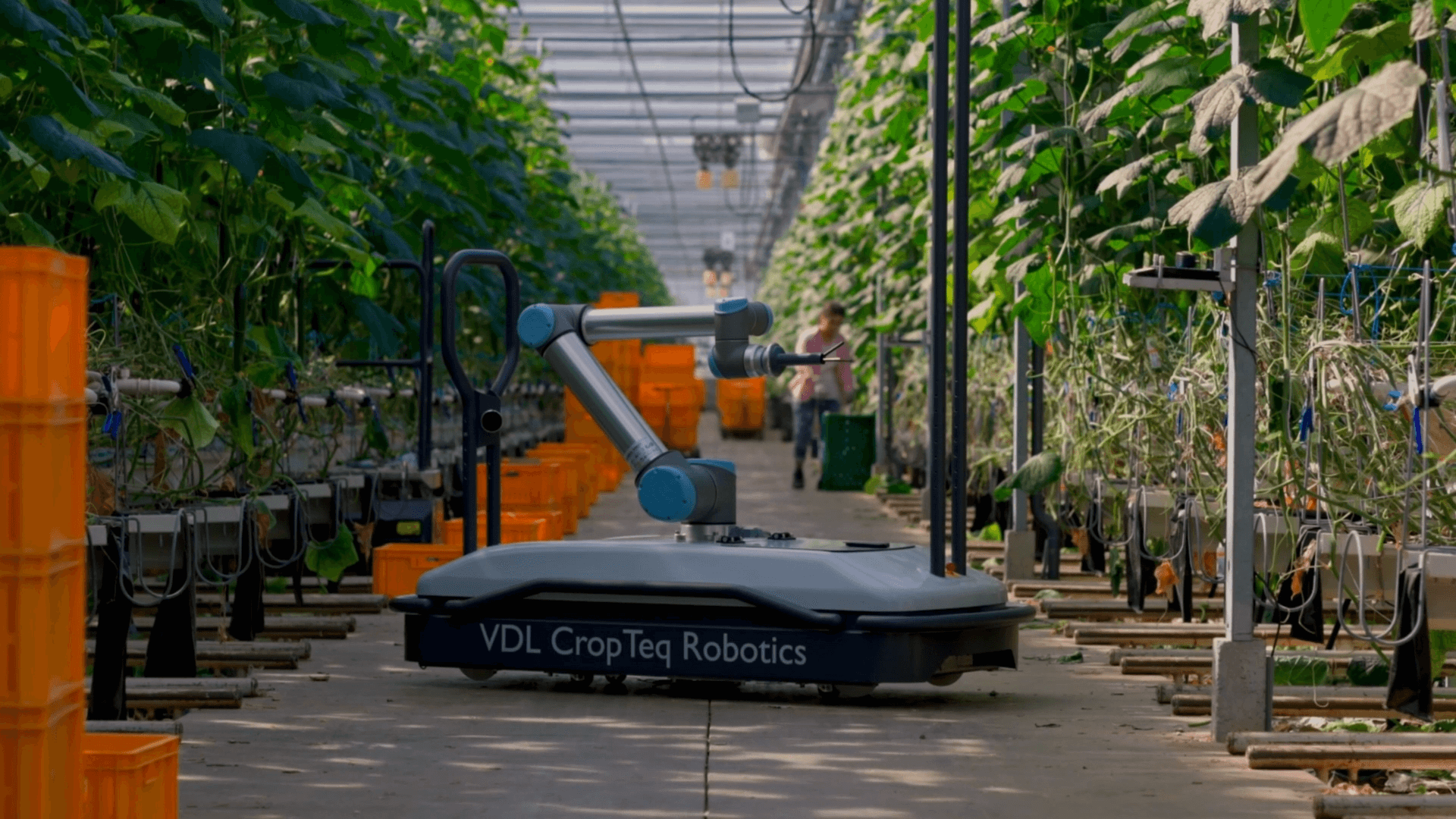

This revolutionary robot is engineered to eliminate repetitive and physically demanding tasks, transforming the landscape of labor-intensive leaf cutting for growers. Tailored specifically for cucumber and tomato cultivation, CropTeq automates the leaf cutting process, significantly reducing labor costs and ushering in a new era of operational excellence.

Experience the powerful synergy of Polariks and VDL CropTeq in an exclusive partnership that brings a groundbreaking solution to the market. Together, we offer a specialized robot designed for precision leaf cutting in high wire cultivation.

Request a Demo

Download our platform whitepaper

Unlock a deeper understanding of our platform's capabilities by downloading our whitepaper. Dive into the core essence of Polariks, explore its modular ecosystem, and discover how our software aligns with your unique requirements.