OPERATIONS for Machine Operators

Data-Driven Maintenance

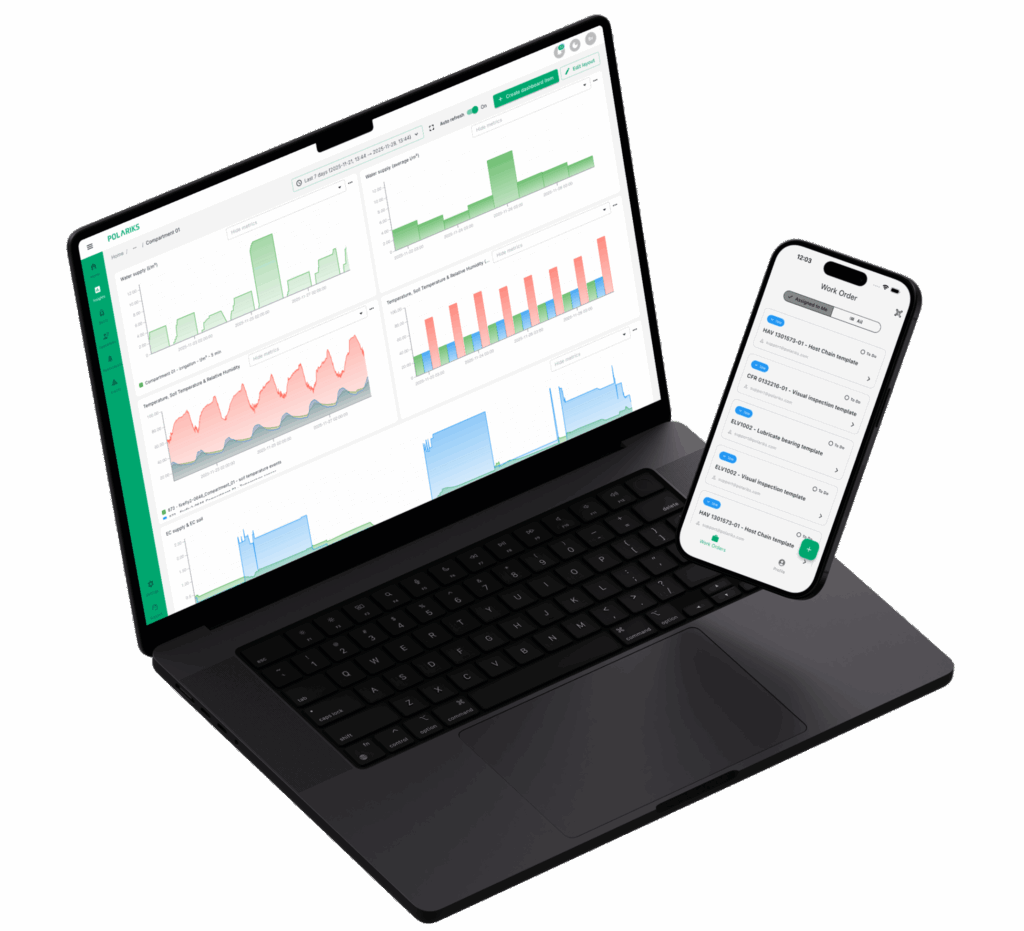

Polariks Operations gives teams the tools they need to work efficiently, reduce risk, and maintain complete control over their environment.

Why

Why Polariks Operations?

Running an organisation means dealing with pumps, motors, valves, machines and everything in between.

When something breaks or gets forgotten, the whole day gets disrupted.

Polariks Operations gives you a clear overview of all machines and tasks, helps you catch issues early, and keeps your team aligned so operations run smoothly instead of reactively.

With real-time insights, automated alerts, and easy communication tools, you always know what is happening, where it is happening, and what needs to be done next.

All-in-one app

What does Polariks Operations offer?

Everything related to your machines, performance, tasks, alerts, history, lives in one clean overview.

No more chasing messages, loose notes, or Excel files.

Work Order Management

Preventive Maintenance

Asset Management

Parts & Inventory

Insights & Analytics

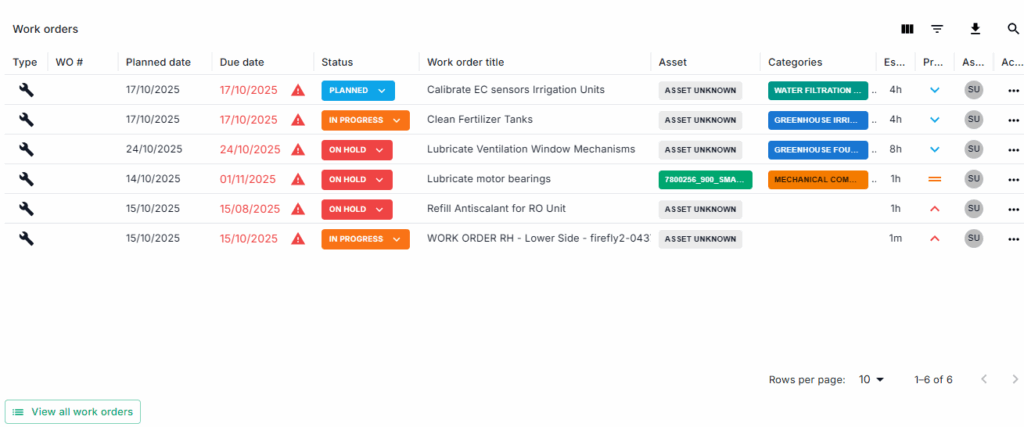

Work Order Management

Complete work from anywhere

Work orders in Polariks are simple and fast to use. You can create a task, add photos or notes, assign the right person, and follow the progress until it’s done.

No more messages, lost notes, or misunderstandings. Everything is organised, visible, and easy to follow. Whether you’re in the greenhouse, packing hall, or office.

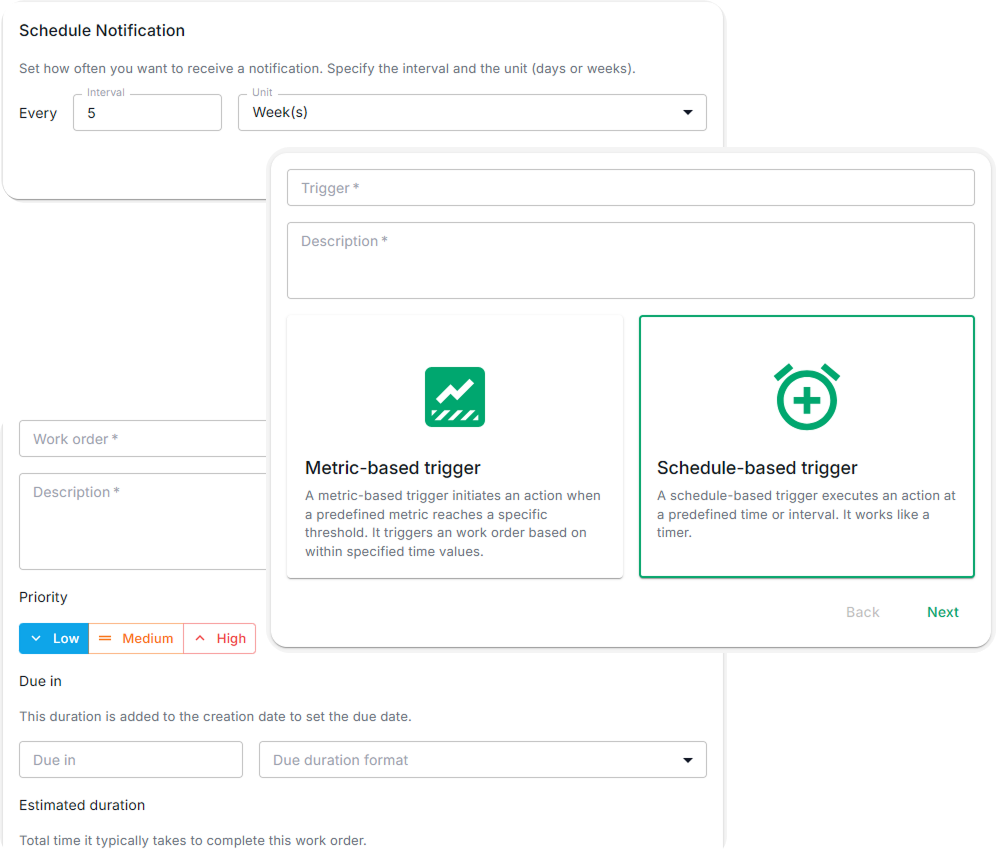

Preventive Maintenance

Reduce downtime

No last-minute stress

Preventive maintenance helps you stop issues before they disrupt production. With Polariks, you can set recurring tasks, send reminders to the right people, and keep track of what has been completed. It’s a simple way to extend machine life, reduce downtime, prevent breakdowns, and keep your operation running smoothly without last-minute stress.

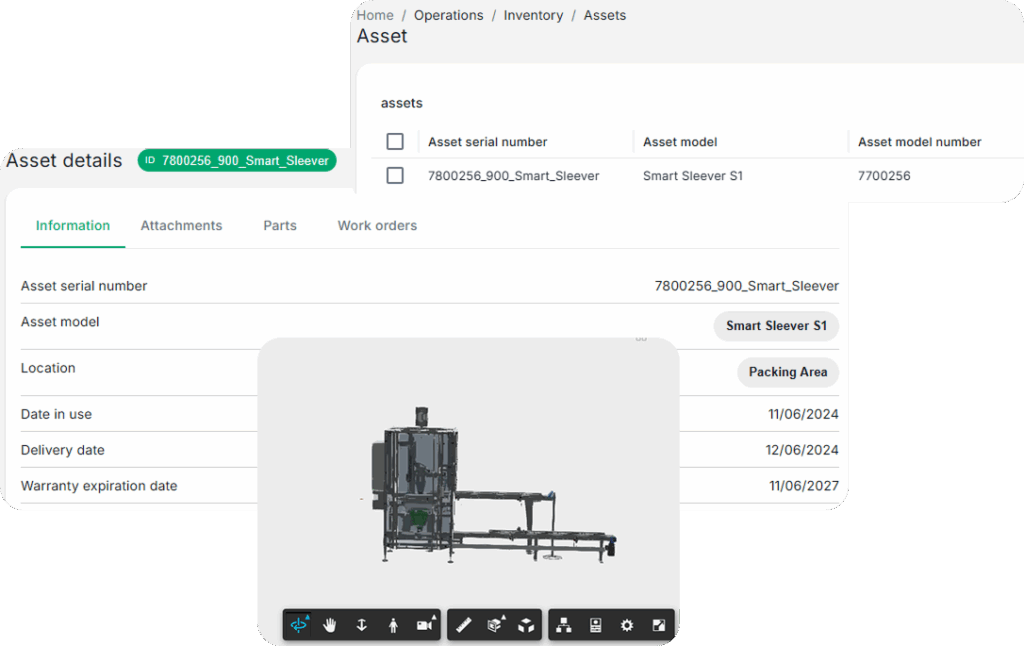

Asset Management

Extend your asset lifetime

Maximize uptime

Polariks gives you a complete overview of pumps, fans, valves, machines, and every other asset you rely on. You can quickly view maintenance history, upcoming tasks, and key specifications for each item. This makes it easier to stay organised, plan work proactively, and make confident decisions about repairs, replacements, and long-term asset performance.

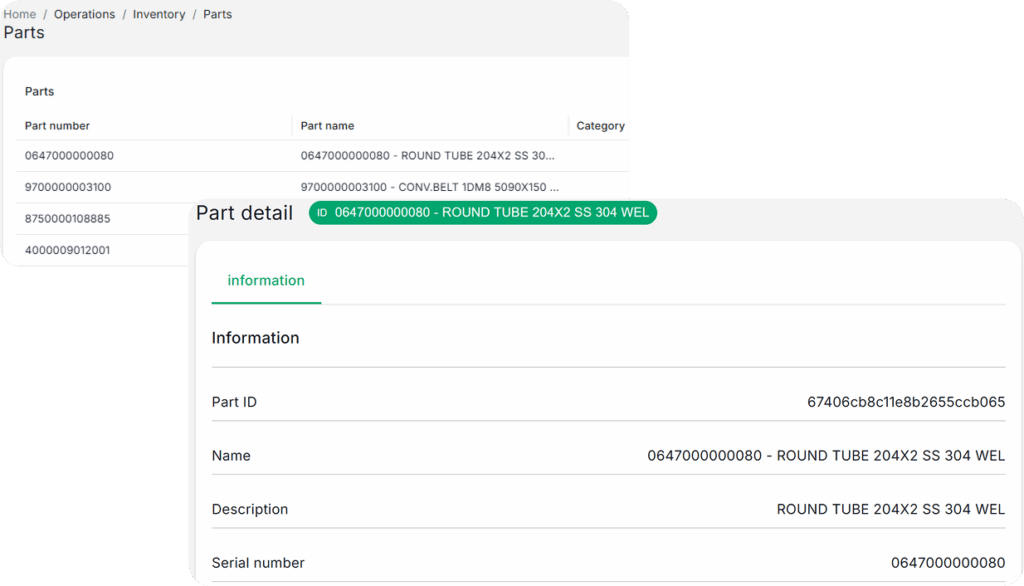

Parts & Inventory

Track spare parts and stock levels so you always have what you need, when you need it

With Polariks, you can manage all your spare parts in a simple and well-organised system. Monitor quantities, locations, and usage in real time, and know exactly when it’s time to reorder. This prevents delays during repairs and keeps your team working faster, smarter, and without unnecessary downtime.

Insights & Analytics

Understand trends, spot recurring issues, and make better decisions with clear, easy-to-use dashboards

Polariks shows you what’s performing well and where problems continue to appear. You get instant insight into machine performance, maintenance costs, task completion, and downtime without needing technical skills or complex reports.

With these insights, you can plan smarter, reduce surprises, and keep your entire operation running smoothly every day.

Features

Simplify maintenance, maximize efficiency

Polariks helps you manage work orders, store important documents, connect all your assets, and oversee multiple locations from one central platform. With everything organised and easy to access, your team can work faster, reduce downtime, and stay in full control of daily maintenance activities.

Vendors

Manage all your vendors, performance data, and service interactions in one organised system.

Integrate Assets

Leverage assets to automate monitoring and receive alerts for potential issues before they escalate.

Photos & Documents

Attach equipment manuals and service reports to work orders and assets for clear instructions, reducing errors.

Multi-Location

Monitor and manage maintenance tasks across multiple facilities & locations world-wide.

Stories

S/1 – OPERATIONS

CreaTech x Polariks

Ready to Take Control?

Monitor, automate and grow your operations, all from one platform.

Join the users already reducing downtime and boosting yield.